Cooperation in industrial production

Wide possibilities are at cooperation in the mechanical production especially in section of stainless and plastic materials. Production base facilities and technical background enables us to deliver complex services.

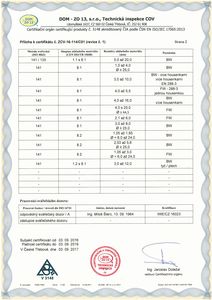

Our company is a holder of ISO 9001:2008 and ISO 14001:2004 certificates.

Contact: Tomáš Janda

+420 728 547 166

tomas.janda@kovofinis.cz

Sheet material indexing

Shearing

- table shears max. material thickness 10 mm, shear length 3 m

Water jet cutting

- metallic and non-metallic materials max. thickness 150 mm, sheet size max. 3000 x 1500 mm

Flame cutting

- carbon steel, max. thickness 200 mm, max. sheet size 4000 x 2000 mm

Plasma cutting

- stainless steel, max. thickness 50 mm, max. sheet size 4000 x 2000 mm

Laser cutting

- carbon steel, max. thickness 20 mm

- stainless steel, max. thickness 15 mm, max. sheet size 4000 x 2000 mm

CNC gantry-type milling machines

- form cutting of plastic and wood-based boards, max. thickness 15 mm, max. sheet size 3600 x 1800 mm

Dimensioning saws

- plastic and wood-based boards, max. sheet size 4000 x 2000 mm, max. thickness 15 mm

Cutting of bars

Band saws

- cutting of metallic and non-metallic bars and profiles up to max. cross section 420 x 420 mm

Forming

Metal sheet forming

- press brake max. bending length 6000 mm, max. thickness of bended material 12 mm – depending on the bending length, computer-controlled process

Metal sheet bending

- max. sheet thickness 14 mm, max. width 2500 mm

Profile bending

- 100/16mm from Ø 500 mm, 35/35 mm from Ø 600 mm

Tube bending

- jig equipment up to tube Ø 108 mm

Welding, soldering

Welding and brazing of metal materials

- welding with – flame, coated electrode, MIG/MAG, TIG

- welded materials – carbon steels including high-grade steel, stainless steel including duplex and super-duplex steel, copper and its alloys, aluminium and its alloys

- brazing with – tin, brass and silver solder

- all joints including preparation are made according to approved procedures (WPS, WPQR)

- all welding work is carried out only by qualified welders and the entire welding process is managed by our own international welding technologist and international welding engineer

- high quality of the welding process control is verified by the standard ČSN EN ISO 3834-2:2006

Welding and bonding of plastics

- welding method: poly-fusion – tubular materials up to Ø 200 mm, sheets up to 30 mm thickness and 3000 mm joint length

- hot air welding with accessory material - limited only by handling dimensions

- bonding - limited only by handling dimensions

Assembly

- we carry out assembly of complex engineering equipment and technologies including assembly, wiring, commissioning, issuing of reports and inspection reports (electrical, hydraulic, pressure air, cooling and others)

- we have trained our own inspection technicians and we also cooperate with external companies

Machining

Turning

- CNC lathes from Ø 50 mm up to Ø 450 mm and workpiece length of 4500 mm

- conventional lathe with max. Ø 320 mm and workpiece length of 6000 mm

- conventional lathe with max. Ø 950 mm and workpiece length of 4000 mm

- range of conventional lathes with different specification

Drilling, boring, milling

- CNC horizontal boring and milling machine series 130, 160 - max. workpiece size is 6000 x 2200 x 1200 mm

- CNC milling machines – max. workpiece (table) size is 800 x 600 x 500 mm

- conventional horizontal boring machines series 90, 100

- conventional milling machines, drilling machines

- hobbing machine for external teeth – max Ø 600 mm, max. module 6

- slotting of internal grooves for slotting machine

Grinding machines

- vertical spindle surface grinding machine – clamping area 300 mm x 1000 mm

- surface grinding machine BPH 20 - clamping area 200 mm x 630 mm, stroke 350 mm

- round grinding machine BHU 40 – ground Ø 400 mm, length 1500 mm

- round grinding machine BUT 63/4000 – ground Ø 850 mm, length 4000 mm

Dynamic balancing

- weight of the balanced part up to 1000 kg, max. Ø 1000 mm, length 4000 mm

Surface treatment

Plating plant

- zinc, nickel, chrome plating – see link

- maximum dimension of parts:

- nickel, zinc plating: 1000 mm x 600 mm x 100 mm

- chrome plating: 500 mm x 400 mm x 100 mm

- electroless nickel plating: 500 mm x 300 mm x 100 mm

Wet painting

- air and air-less (high pressure) application of solvent coatings including system surface finish in two booths of 15000 x 5000 mm each

Powder coating plant

- powder coating in line or in a separate booth, max. size: 600 x 1100 x 900 mm – see link

Blasting

- chamber blasting machine max. size 2200 x 2200 mm, blasting with steel granulate

- continuous blasting machine for bar material, max. cross-section 400 x 400 mm, blasting with steel granulate

Stainless steel etching

- dipping, tank size 3500 x 3000 x 1000 mm

- spraying

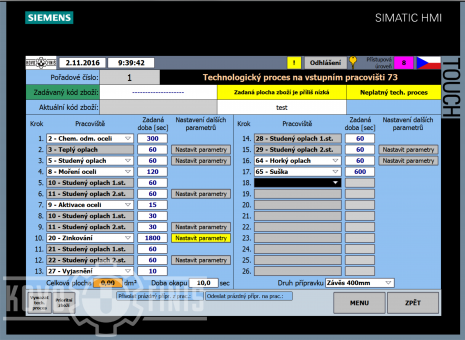

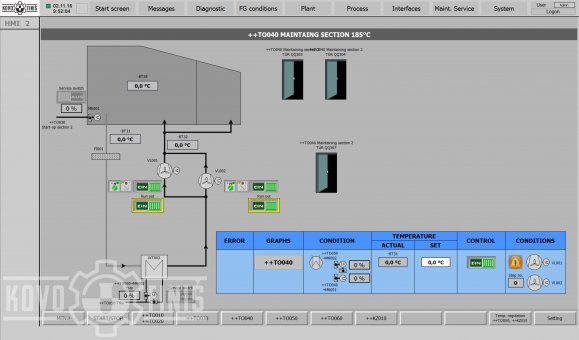

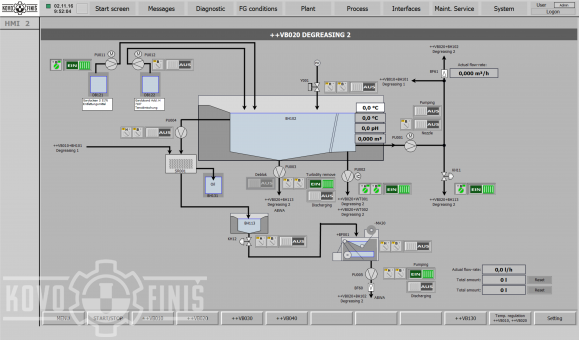

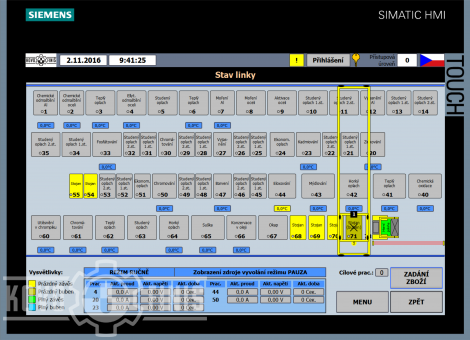

Control and visualization systems - Automation

Control and visualization systems - Automation

We supply complete software control of the entire technological process to our plants. Automatic control of the line/plant operation reduces the amount of human labour required, increases plant efficiency and ensures consistent quality results. Despite the initial higher investment, automatic plant control is economically more advantageous than manual control due to higher productivity, consistent process quality and lower operator requirements.

The software solution is the result of development by our own programming team and is continuously being improved. We are therefore not dependent on an external control system supplier. For each customer we design an order-made control system to meet their requirements and ideas. We always run our systems on the latest version of the SIEMENS Simatic platform, which allows almost unlimited flexibility of the solution.

Thanks to our system, production can be planned efficiently. The system efficiently plans the use of production line capacity. The system performs simulations of future operations so that it can accurately plan individual line operations and schedule the passage of goods through the line to achieve optimum line utilization while adhering to all specified recipes. The system clearly displays all this information to the line operator on a touch panel at the line or on a PC. The operator thus knows exactly when and in what order the goods will be returned to him before the operation starts. The line operator can therefore focus primarily on the inlet and outlet sections of the line and leave the rest to our system, which takes care of the rest.

The system allows freely programmable recipes, as well as a custom recipe for each rack in the line. There can be multiple items in the line at one time, each with its own recipe. The automation system itself resolves any collisions and plans the optimal passage of goods through the line.

Our systems communicate with each other! The system controlling the surface treatment line communicates with the system controlling the WWTP and vice versa. This prevents production deficit and overcrowding at individual nodes. For example, the line knows exactly when it can discharge waste water to the WWTP. It also knows, for example, exactly how much DI-water it has ready in the treatment plant and can plan its production in advance so that there is never a shortage.

Automatic regulation of:

- temperature

- current

- levels

- dosing

- movements and lifts etc.

Visualization of technology process

- on PC monitor or touch screen near the device or remote workplace:

- display of equipment operation

- fault warning

- data recording and storage, parameters statement and print

- actual parameters statement (print) as well as the reverse statement for the queued protocol

- different access level - access password

Archiving:

- goods archive: parameters for each charge (goods code, date and real time, operating times, temperatures)

- event archive: date and time of line start, fault conditions, pause occurrence, dosing of additives

- performance archive: number of charges per time period

Service

We provide warranty and post-warranty service for all supplied equipment, including the supply of spare parts.

The service includes complete care of the supplied equipment including the provision of a preventive service program.

We offer:

-

assistance with equipment start-up and production start

-

regular inspections to prolong the uptime of the equipment

-

on-demand service including service interventions within 24 hour

Consulting

Our experts are ready to provide their knowledge to resolve customer's questions in surface treatment and waste water management.

We offer our full help in dealing with government and environmental authorities during approval procedures.

Welding school

Welding school

We run our own welding school, unfortunately the lectures are held only in Czech language.

Electroplating line

Technological workplace for electroplating enables us to implement testing a surface treatment technology development. We can provide our customers with samples of surface treatment on their own goods to see the quality of our technologies. We offer our customers to work with us on developing new surface treatment technologies.

We are ready to provide zinc plating, nickel plating, electrochemical brushing of stainless steel and iron bluing. We can provide samples of zinc plating, copper plating, nickle plating and chromating in our research laboratory. We are willing to offer samples of other less common surface treatment methods not mentioned above.

Zinc plating

- blue chromate, yellow chromate

- barrel: mass production

- rack: max size of goods 1300 x 700 x 200 mm, max weight of goods 100 kg a piece

Nickel plating

- barrel: mass production

- rack: max size of goods 1300 x 700 x 200 mm, max weight of goods 100 kg

- chemical nickel plating: max size of goods 400 x 400 x 400 mm, max weight of goods 20 kg a piece

Electrochemical brushing of stainless steel

- max size of goods 1500 x 600 x 200 mm, max weight of goods 50 kg a piece

Iron bluing

- max size of goods 1300 x 600 x 200 mm, max weight of goods 120 kg a piece

Rack and mass production zinc plating

- max size of goods 1200 x 350 x 650 mm

Rack and mass production copper plating, nickel plating and chromating

- max size of goods 1200 x 350 x 650 mm

Electroplating of plastics (ABS, ABS/PC, 2K parts, PA6 MD45)

Chrome (2ZZ, 3Q7, Silver Shadow, Perlglanz, etc.)

- hexavalent, incl. pretreatment

- trivalent

- chrome-free pretreatment (Cr6+ FREE)

Nickel – microporous / (microcracked)

Nickel – bright / satin

Design type – exterior / interior

Contact:

Jaroslav Jelinek

e-mail: galvano@kovofinis.cz

Powder paint coating line

Powder coating is an excellent choice for the protection and aesthetic treatment of surfaces in various industries. Its advantages include high resistance to damage, abrasion and corrosive effects, ensuring a long service life of the coating. Thanks to the electrostatic application of the powder coating, a perfect and uniform coverage with long durability can be achieved.

Another advantage of powder coating is its ecological and economic efficiency. The process is environmentally friendly, contains no solvents or volatile substances and minimises waste, resulting in reduced operating costs.

Due to its versatility and ability to paint various types of metal materials, powder coating is the ideal solution for many applications. It is a fast and efficient way to achieve a durable and aesthetic surface finish. The result is a quality and durable finish that meets the highest standards.

Our own powder paint coating line is equipped with

- Surface pretreatment section (degreasing, phosphating, rinsing)

- Powder paint coating section

- Drying section

- Hardening section

Basic data